Have you ever wondered how the humble but ever enduring concrete came about? In this post, we find out its history.

Early Use of Concrete

The first concrete-like structures were built by the Nabataea traders or Bedouins who occupied and controlled a series of oases and developed a small empire in the regions of southern Syria and northern Jordan in around 6500 BC. They later discovered the advantages of hydraulic lime — that is, cement that hardens underwater — and by 700 BC, they were building kilns to supply mortar for the construction of rubble-wall houses, concrete floors, and underground waterproof cisterns. The cisterns were kept secret and were one of the reasons the Nabataea were able to thrive in the desert. By about 5600 BC along the Danube River in the area of the former country of Yugoslavia, homes were built using a type of concrete for floors.

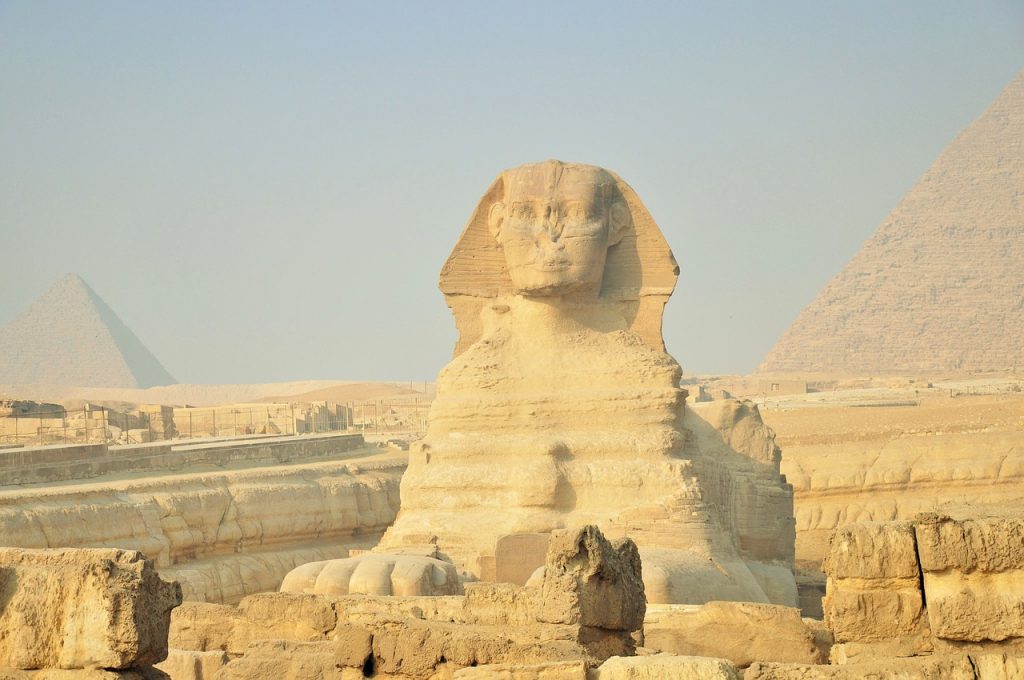

Egypt

Around 3000 BC, the ancient Egyptians used mud mixed with straw to form bricks. Mud with straw is more similar to adobe than concrete. However, they also used gypsum and lime mortars in building the pyramids, although most of us think of mortar and concrete as two different materials. The Great Pyramid at Giza required about 500,000 tons of mortar, which was used as a bedding material for the casing stones that formed the visible surface of the finished pyramid.

China

About this same time, the northern Chinese used a form of cement in boat-building and in building the Great Wall. Spectrometer testing has confirmed that a key ingredient in the mortar used in the Great Wall and other ancient Chinese structures was glutenous, sticky rice. Some of these structures have withstood the test of time and have resisted even modern efforts at demolition.

Rome

By 600 BC, the Greeks had discovered a natural pozzolan material that developed hydraulic properties when mixed with lime, but the Greeks were nowhere near as prolific in building with concrete as the Romans. By 200 BC, the Romans were building very successfully using concrete, but it wasn’t like the concrete we use today. It was not a plastic, flowing material poured into forms, but more like cemented rubble. The Romans built most of their structures by stacking stones of different sizes and hand-filling the spaces between the stones with mortar. The Colosseum was completed 1,937 years ago, and it stands today as one of the enduring symbols of the Roman Empire—and more literally as a testament to the endurance of Roman concrete.

The Pantheon

Built by Rome’s Emperor Hadrian and completed in 125 AD, the Pantheon has the largest un-reinforced concrete dome ever built. The dome is 142 feet in diameter and has a 27-foot hole, called an oculus, at its peak, which is 142 feet above the floor. It was built in place, probably by starting above the outside walls and building up increasingly thin layers while working toward the centre.

Middle Ages

After the Roman Empire, the use of burned lime and pozzolana was greatly reduced until the technique was all but forgotten between 500 and the 14th century. From the 14th century to the mid-18th century, the use of cement gradually returned. The Canal du Midi was built using concrete in 1670.

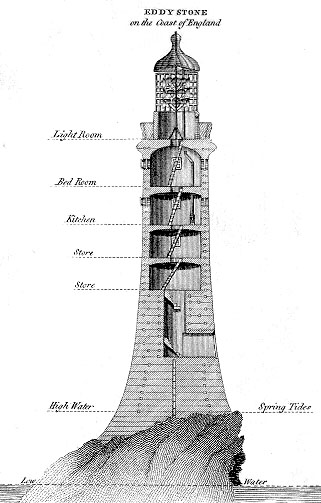

Industrial era

It wasn’t until 1793 that the technology took a big leap forward when John Smeaton discovered a more modern method for producing hydraulic lime for cement. He used limestone containing clay that was fired until it turned into clinker, which was then ground it into powder. He used this material in the historic rebuilding of the Eddystone Lighthouse in Cornwall, England.

Finally, in 1824, an Englishman named Joseph Aspdin invented Portland cement by burning finely ground chalk and clay in a kiln until the carbon dioxide was removed. It was named “Portland” cement because it resembled the high-quality building stones found in Portland, England. It’s widely believed that Aspdin was the first to heat alumina and silica materials to the point of vitrification, resulting in fusion. During vitrification, materials become glass-like. Aspdin refined his method by carefully proportioning limestone and clay, pulverizing them, and then burning the mixture into clinker, which was then ground into finished cement.

- World’s biggest single structure house 3D printed in one go - July 27, 2020

- Compulsory registration scheme for NSW professional engineers - June 29, 2020

- The Moore Shire Bituminised Road - June 22, 2020

- Bioinspired Structure with 3D Printing - June 15, 2020

- Doughnut Economics: Amsterdam’s Green Recovery Plan - June 1, 2020

- These 5 cities are turning roads into bike lanes because of coronavirus - May 18, 2020

- Four Australian among the world’s top ten universities best placed to solve the world’s biggest challenges - May 11, 2020

- This is how South Korea is balancing getting people back to work and protecting their health - May 4, 2020

- These 5 cities are turning roads into bike lanes because of coronavirus - April 20, 2020

- What is Concrete Temperature Limit? - April 13, 2020